GENERAL DESCRIPTION - THE DIFFERENCE BETWEEN FIBER & CO2

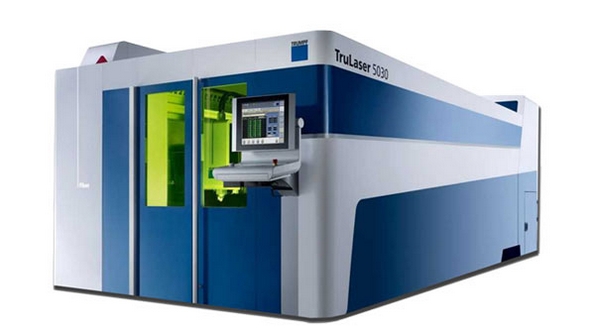

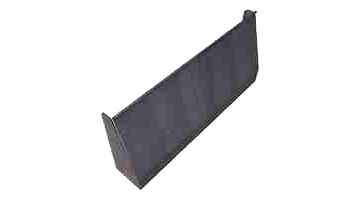

Our fabrication facility is equipped with both C02 and Fiber Laser Cutters.

Which laser cutter is better for your specific application?

We will try to explain the pros and cons for both technologies.

The obvious difference and benefit is speed: the fiber laser cutter is five times faster on thinner gauge material than it's C02 predecessor, which improves turnaround times and lowers costs.

FIBER LASER CUTTER - HOW IT WORKS

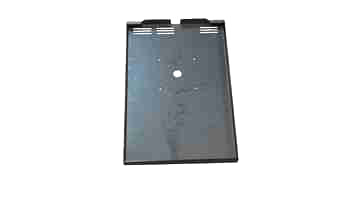

The fiber laser cutter is designed so that fiber laser light is created by banks of diodes. The light is directed through a channel and intensified through fiber optic cable similar to that used for data transfer. The amplified light is straightened and then focused by a lens onto the material, creating the cutting action.

The fiber light methodology is 200% more efficient than traditional CO2 laser technology . The focusing lens is sealed in the cutting head and is not a consumable item , unlike the C02 laser cutter.

PRICE TO PERFORMANCE

When examining the price-to-performance ratio of the two machines, the main benefit is the cutting speed for materials 28 gauge to 10 gauge thick.

Another benefit includes thickness capacity. The fiber laser cutter can handle much thicker materials.

The benefits of a fiber laser cutter

1. Unlike a conventional CO2 laser, there are no moving parts or mirrors at the light-generating

area, which offers greater advantage for reducing operating and maintenance costs.

2. Lower running costs and electrical efficiency. A fiber laser cutting machine uses one third of the power of a CO2 laser.

3. When cutting thin material, the fiber cutter uses higher speeds: it is three to four times faster in straight cuts of 1 mm mild, galvanized, or stainless steel, and twice as fast when cutting 2 mm material.

4. The fiber laser cutter has the aptitude to cut reflective materials without destructive back reflections that could potentially damage the machine. This machine can effectively work with materials such as copper, brass, and aluminum.

5. On comparative projects, the fiber laser cutter offers 50% lower servicing costs versus the CO2.

The major benefit of a CO2 laser cutter is the speed with which it can cut materials 3/16” and thicker, compared to the fiber laser. Edge quality can also be better on this machine, on heavier gauge sheet.

CLIENT BENEFITS

In the last 5 years, the demand for quicker lead times has increased. As a job shop, we recognized this need, and to accommodate our clients, we purchased the fiber laser cutter for its speed on thin gauge materials.

Lower power consumption and diversity of materials we can process were two other reasons behind the purchase of this machine.

OUR EXPERIENCE

For three months, we ran both the fiber laser cutter and C02 laser cutter side by side, and from our experience we can honestly say that in terms of speed and quality of cut, the fiber machine greatly exceeded our expectations. The quality of cut is very reliable without adjustment, and the speed of the machine is typically two to three times faster.

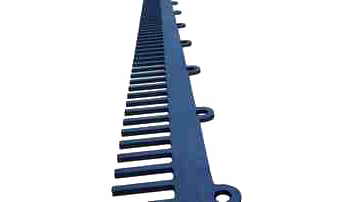

The ability to process copper and brass is also extremely advantageous, since the CO2 laser can’t work with these materials.

The machine can cut so fast that for certain jobs, the operator can’t keep up with the loading and unloading of the machine

QUALITY

With our basic testing, the quality of material 3/16” and below on the fiber is a step up from the CO2 laser machines. Over 3/16”, quality is comparable between the two machines.

So far there have been few quality issues, with no burrs on the edges of the cut, and finished parts within set tolerances.

SUMMARY

Ever since we've started using the fiber laser cutter, we've been very happy with the quality and speed.

The initial plan for the fiber laser machine was to help with our big repeat jobs, and to speed up production to offer our clients a quicker turnaround.

We are also pleased with the profile cutting of yellow shiny metals such as brass and copper.

The fiber laser cutting machine is a great addition to our overall sheet metal fabrication production.

SHEET METAL PRODUCTION SERVICES

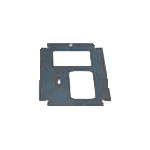

Our dedicated production team communicates with clients through all stages of the production process. At the onset of the production, we will assign a project manager to work with you and develop your drawings. If needed, we will offer ideas to streamline the production process and pass on the savings to you. Depending on your design specifications, whether you have a rough sketch or a computer drawing, we will offer the most cost-effective solutions, and the most viable production process for your project.

If needed, we will assist you with sourcing material through our list of reliable vendors. Production personnel will ensure quality parts with a high-precision CNC machine. We are a one-stop shop, operating automated fabrication machinery to achieve all aspects of production in house. We've been a job shop for nearly forty years.

If you require a prototype component, we are experienced in conducting test analysis to ensure the needed results. We will always work with our clients to better their design ideas, and make sure that the finished part perfectly resembles your drawings. We like to take on challenging prototype jobs that require experience, test analysis, and precision fabrication. At Stollco Industries, all jobs are fabricated to perfection.

Our workers focus on their tasks and workstations, and are encouraged to communicate with each other. From designer to project manager to front line fabricator, all parties are involved in open discussions. If issues arise, the client is offered several solutions. We are proud to work as a team to produce the most economical and highest quality product for our clients.

At Stollco Industries, we have a low tolerance for imperfections. Our policy of zero-defects and high quality is the main reason for our longevity and success. The team understands that one defective part could result in a defective product down the line. We have checks in place to ensure that all products are fabricated as per your specifications. We pride ourselves on our work.

Our engineering team works alongside our production team. From concept, to design, to completed products, we will offer a complete sheet metal fabrication service. Our fully automated facility showcases the latest CNC equipment and the experienced operators. We provide knowledge and design assistance to all of our clients. We take pride in our philosophy of a zero-defect part, and high standards.

At Stollco Industries, we are here to exceed your expectations.