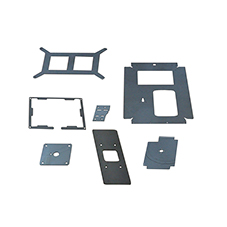

2 LASER CUTTING MACHINES LASER CUTTING METAL SERVICES

PREFERRED MATERIALS FOR EACH MACHINE

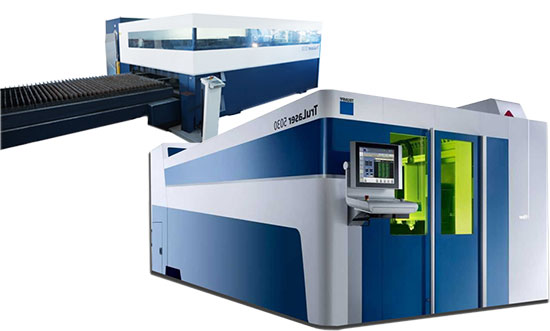

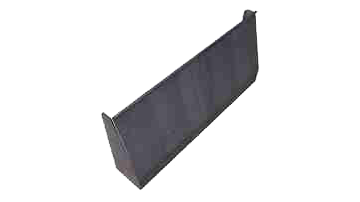

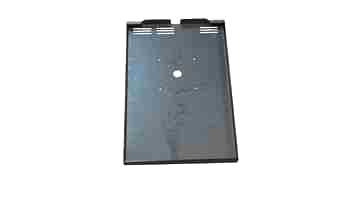

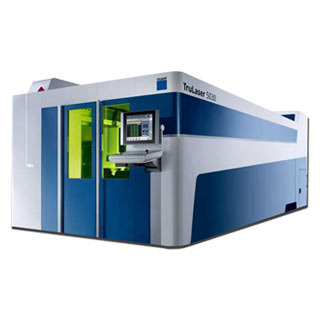

We own a C02 Laser Cutter and a Fiber Laser Cutter. Depending on the material, the fiber cutter is

five times as fast as the C02 laser cutter, which helps provide quick turnaround time. Both our

machines provide cuts that are always within the specified tolerances, and they deliver high

quality cuts with no edge burns. With the addition of our fiber cutter, we can easily produce

profile cutting of shiny materials such as brass and copper.

With all metal based materials, we deliver high performance, fast lead time, and great pricing.

LASER CUTTING PRODUCTION PROCESS

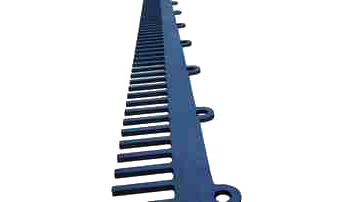

We are known for high volume laser cutting jobs but also, we like to accept challenging laser cutting jobs that require a high level of engineering expertise. We built a solid reputation and great relationships by taking on small one off jobs. We believe in client satisfaction.

Our production team consists of our designer, production manager, and our CNC operators. Our production manager consults with the client. The production manager takes our client's idea to our design team.

We understand that we are here to provide our knowledge and expertise. We suggest and provide the best approach for the production process.

Once our client approves of the process, and we start production. Throughout the production process, we are in constant communication with our clients. The main philosophy of our over the top service is quality, precision and on time delivery.

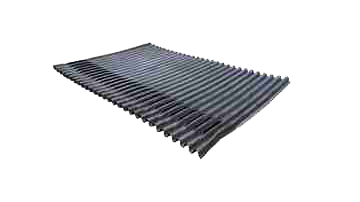

Our laser cutting operators understand industrial applications and have mainly worked with mild metal, sheet metal and steel plates.