METAL CUTTING CAPABILITIES & SERVICES

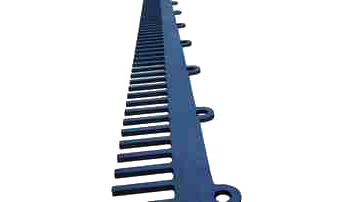

Our metal fabrication facility contains experienced people, along with the most advanced CNC technology. We specialize in laser cutting metal, and are equipped with two laser cutting machines that allow us to manufacture various industrial components and parts: we love to work on unique projects.

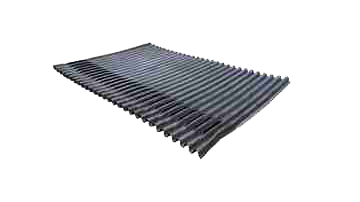

Both of our Trumpf machine sallow for multiple processes, including intricate cutting, production cutting, tube cutting, and etching. There is almost no limitation to the profiles we are able to cut.

The laser cutting machines produce smooth edges, and are capable of etching components, eliminating the need for stamping part identification further down the production chain. In most cases, laser-cut components are complete, requiring no additional finishing process.

Our experienced production team works under the direction of the project manager, with a focus on meeting, and even exceeding, our client’s expectations. The team is in constant consultation with our clients, planning and analyzing the production process the whole time. From concept to completion, we will work with the client to assist in all levels of the finished product, from material sourcing, to quality control, and to final delivery. Throughout the project, our team maintains consistent communication with the client, providing updates on the stage of the production.

Stollco offers design assistance with existing applications, as well as with prototypes. Our experienced design engineers collaborate with the skilled production team to reduce costs, increase deliveries, and potentially improve product design. We will develop a 3 D model before parts are finalized for production, and the initial designs usually undergo several rounds of design revisions. We place a high degree of emphasis on perfecting the final product, utilizing our experts to oversee the entire prototype engineering process, from design assistance, to research and development, all the way through prototype manufacturing.

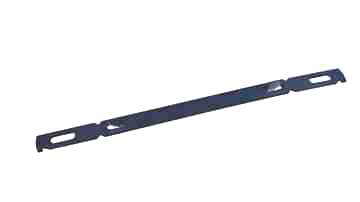

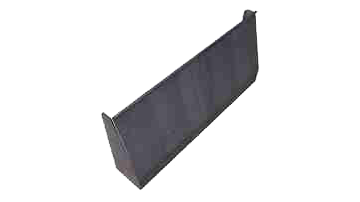

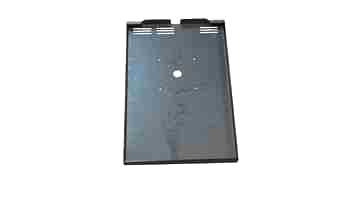

Stollco designs and fabricates various structural, electrical, and mechanical components, including but not limited to custom brackets, electrical chassis, enclosure boxes, instrument panels, and underwater tanks.

We specialize in providing metal cutting services to all industries. Depending on the level of output, our machines are designed for both high-volume and low-level production. The production team will quickly service your specific applications, utilizing our detailed knowledge and expertise for your project. We offer exceptional one-stop shop fabricating services.

We are always looking for ways to help our clients succeed.