SHEET METAL FABRICATION SERVICES FOR THE GREATER VANCOUVER AREA AND FRASER VALLEY

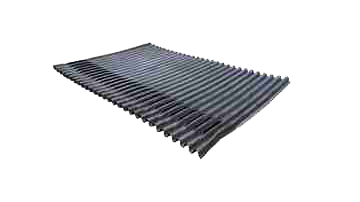

Stollco Industries is known for its job shop services. We are a one-stop-shop for CNC machining and tool and die making services. Our production team in conjunction with our engineering team produces products for all industries. From concept to design to completed products, Stollco will offer a complete sheet metal fabrication service. We have extensive experience manufacturing sheet metal fabrication components, brackets, electric chassis, instrument panels, tools and other custom fabrication works. We have the experience to work for industrial, commercial, electronic, and mining industries.

FABRICATION SERVICES FOR THE VANCOUVER AREA

Throughout or inception we've maintained our client base. The reason for our success is our commitment to our client's end goal. We understand that we are here to provide our “detailed knowledge” and years of experience. We always work in partnership with our clients to provide the best service in the industry. We offer our own style of "over-the-top" service. We've developed our reputation by getting the job done right. We ensure that all clients enjoy their experience with Stollco. Our clients become our friends.

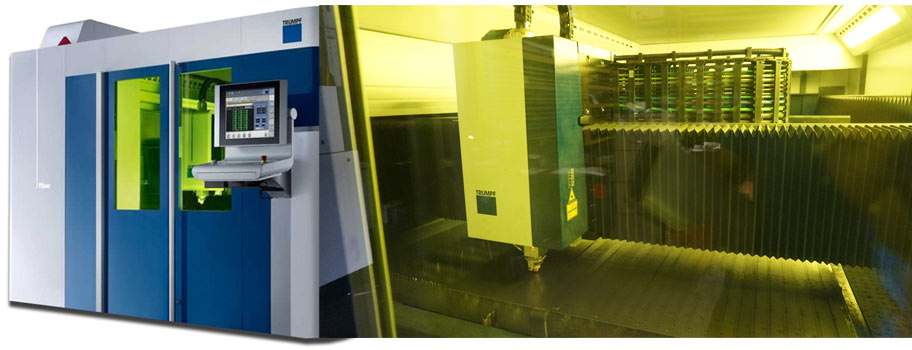

LASER CUTTING SHEET METAL AND DESIGN ASSISTANCE

At Stollco, we are an extension of our clients design team. We view all drawings, and if needed, we offer our ideas. We like to take on challenging designs. From concept to completion we work with our clients through design, development, testing, prototyping and finally the finished product. Weather you give us a rough paper sketch, or a computerized 3-D model, we will help complete your design. Our team of dedicated engineers will always offer ideas that will lower costs and increase efficiency. We are here to provide our engineering knowledge and fabricate products that produce results.

STOLLCO PRODUCTION PROCEDURES

For our clients, we work to make the production experience effortless. Our clients communicate directly with the production team. We assign one production manager to each project. Our production manager will assist you in all stages of the production process. Our production manager will communicate your ideas to our engineering team. Our programmers will offer the most cost-effective set up for your design. Our expert programmers will develop a stream line automated CNC machining plan that will decrease cost and increase production. The production manager will collect and administer records of the production time and production processes. After the fabrication is complete, and if needed, we will conduct a test analysis that will ensure that fabricated components fit accurately into place. For components that require strict tolerances, we are the company of choice. Our approach and our precision fabrication methods will deliver components that work right the first time, every time. We ensure that all our finished fabricated products will perfectly resembles your design specifications. We like to take on unique applications that require precision fabrication. At Stollco, all jobs are fabricated to perfection.