FABRICATION SERVICES & METAL CUTTING

QUALITY, EFFICIENCY, & VALUE

We operate an efficient fabrication facility, producing quantities from individual prototypes to batch volumes. There is coordination between all processes, resulting in high quality, efficiently made parts. Our streamlined procedure translates means value for our clients.

OUR SERVICES

We have an experienced design team, and offer engineering assistance as well, to transform your ideas into fabricated realities. We recognize and appreciate the expertise you have in your field, and aim to show you how proficient we are in ours.

Every product is specific to our client, and their industry. For over four decades, we have worked with various industries, approaching every opportunity with a great understanding of the end result, offering design improvements where warranted.

Our consulting methods help the manufacturing process. Stollco designers and machine operators are always looking for ways to increase production, allowing us to pass on the savings to you.

Every department practices the philosophy of zero-defects and high quality, with our mantra being “perfection.”

When other companies say “we can't," we say "we can." We hope to exceed your expectations.

QUALITY OUTPUT

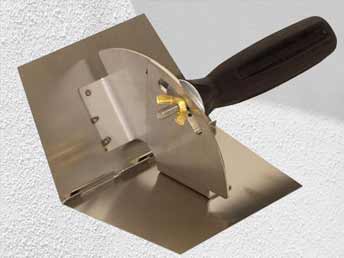

For standardized operations, we utilize a sequential flow production process, in an assembly line fashion from one operation to the next (e.g. from laser cutting, to pemming, to forming, to welding). The work capacity and quality at each stage is constantly being analyzed by our production manager, ensuring a smooth flow of work, and parts within tolerances.

This approach is for standard operations, where the production manager can easily gauge the process at each stage, and predict the completion of the order. We can also easily manage material requirements and information flow. The benefit of this production style is the relative ease with which to increase work volumes.

PLANNING AND SET UP

The set up or planning stage is as important as the production process. Our production manager will prepare the material, consult with the machine operator (if necessary), and generally keep an eye on the entire flow of the manufacturing process. All needed materials, tooling machinery, and assembly workstations are set in motion with a designated plan developed by our people. Complex assemblies require more set up time than the standard batch production.

PRODUCTION WORKSTATIONS

Our workplace We help our workers focus on their job. We make our teams workplace as ergonomic and comfortable as possible, so that workers are able to focus on their work.

Workstations that are organized and accessible make our employees job seamless, which results in production efficiency. The tools are located in their proper places and are fully functioning, ready for use. The tables are at the optimum height for our worker. The materials are placed in their assembly carts at its designated location.

The production for each workstation in the production process are pre-determined. The production sequence is specifically designated by the production manager. Instructions accompanied by checklists are posted at each workstation to ensure proper follow through.

By developing clear instructions, our production understands that their workstation will need to be ready for operation at all times. All machine operators are responsible for ensuring that their workstations are fully functional and ready for operation.

Our production team is responsible, self sufficient and willing to meet high expectations.

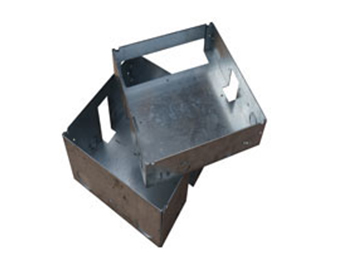

MANUFACTURING COMPONENTS

When manufacturing a component made from various parts, all component parts are fabricated within a production sequence. We place all the parts on an assembly cart or crate. Each batch is carted from one operator to the other. A production manager keeps a record of the transition, and he gauges the quality of the finished product from each station. Our procedure eliminates quality problems, temporary storage, and product imperfections.

For every job, we maintain our focus and manufacture all components to their exact specifications.

Fabrication of parts sets begins in the design stage. In the design department our engineers direct the parts through sequence of tooling and machining. If a complex component is directed to be cut on a laser cutting machine in a single work cycle, the designer will direct the laser cutter to perform various tooling actions, such as cutting, profiling etc.

LEARNING AND GROWING

Continuing education of each employee is highly important at our facility. We promote workers understanding multiple disciplines. They not only perform tasks at just a single workstation, but perform the tasks at the multiple workstations. This allows our team freedom to work together with the product through the multiple workstations / multiple skill sets. Instead of carrying out the same operations at one station day in and day out, they are empowered to understand the entire scope of production. It's a considerable amount of training on our part, but the end result yields an educated production team.

CHECKS AND REVIEWS

We are never satisfied with our production methodology. We understand to stay ahead of the competition we must be willing to learn and grow.

To help our team advance and grow, we perform reviews at regular intervals. Unless otherwise requested from our people, the results of the reviews are shared for everyone to see. The goal is to highlight achievements and enable further improvement, which will steer our production associates from bad habits and bad production practices. We use our review policy as an opportunity to train and allow our workers to advance themselves. A good production manager not only checks off items on a list, and evaluate the results, but also acts as a coach, providing tips and most importantly helps our people develop solutions.

Our checking process motivates our people to offer solutions. We attain great knowledge and data

from the front line. We address their needs and create an environment of success.

The fundamental highlights of our review program is allowing and focusing our people to become

solution oriented thinkers.

When our people offer solutions, we grow, and as a result, our clients receive discounted prices without reducing quality or efficiency.

OUR PRODUCTION GOAL

From our designers to production managers to our machine operators, we instill a pride of getting the job done right the first time and every time.

We are large enough to handle batch orders and small enough to produce one off prototype parts. Our success is derived from our people. We encourage our people to communicate with one another. All departments have full access to our management team. We offer a great work environment so that our people are motivated to fabricate quality components that will exceed our clients expectations.

As discussed, the planning stage and set up stage is as important as the production stage. At this stage we prepare a plan that will be executed without quality issues and deadline delays.

We've been in the business of fabrication for three generations, and enjoy the process of fabrication. We will exceed our clients' expectations.