SHEET METAL FABRICATION SERVICES

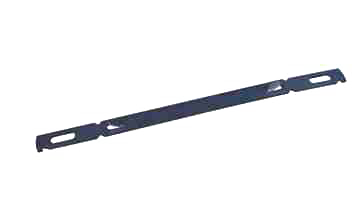

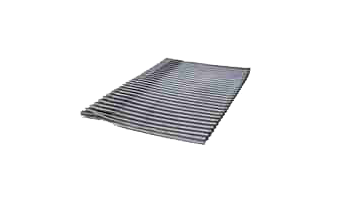

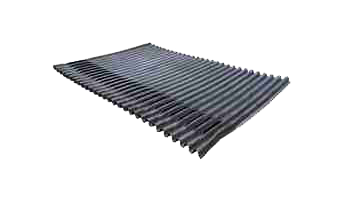

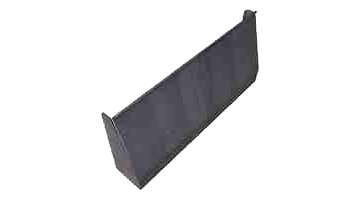

Stollco Industries manufactures various sheet metal fabrication products for industrial, commercial, electronic, and mining industries. A job shop for custom fabrication works, Stollco designs and builds components such as: brackets, electric chassis, instrument panels, tools and other custom fabrication works.

DESIGN ASSISTANCE FOR FABRICATED COMPONENTS

Our designers have decades of experience. We have an in-house design team that will work to facilitate our clients' needs. Most clients rely on our ideas to better their conceptual drawings. Based on our knowledge and expertise, we like to help our clients through the design process. We assess all drawings and provide the best methods of design and production. When designing metal fabrication components, we take into account factors such as the nature of the end product, the type of application, and the environmental conditions. Our designs are subjected to numerous tests before being finalized for production. We understand that we are here to provide our “extensive knowledge” and years of experience. We offer ideas that will exceed your original expectations. We offer the "Stollco" over-the-top sheet metal fabrication service.

PLANNING AND SET UP

The set up or planning stage is as important as the production process. Our production manager will prepare the material, consult with the machine operator (if necessary), and generally keep an eye on the entire flow of the manufacturing process. All needed materials, tooling machinery, and assembly workstations are set in motion with a designated plan developed by our people. Complex assemblies or large sheet metal fabrication jobs require more set up time than the standard batch production.

SHEET METAL FABRICATION, CNC MACHINE SHOP, AND TOOL & DIE

In conjunction with our CNC machine shop operations, we have a tool and die maker. We can fabricate almost any custom sheet metal component under one roof. We excel at developing the entire package, design, prototype, testing and final product. We are large enough to offer a one-stop-shop sheet metal fabrication services but we are small enough to provide personal service. Our clients communicate directly with the decision makers.

STOLLCO PRODUCTION PROCESS

Our team of dedicated production professionals will assist you in all stages of the production process. We will assign a project manager to work with you and communicate your ideas to the engineering team. Depending on your design work, weather you have a rough sketch or a completed product design, our team of experienced engineers will offer the most cost-effective solutions for your concept. We can assist you with sourcing material and services by using our extensive list of reliable suppliers. At the production stage, we will consult with you on all production aspects throughout the process. We keep an accurate record of the production time and production processes. We make sure the finished product perfectly resembles your drawing specifications. Especially for strict tolerances, our high-quality standards deliver the intended results. We like to take on challenging jobs that require precision metal fabrication. At Stollco, all jobs are fabricated to perfection.

QUALITY, EFFICIENCY, & VALUE

We operate an efficient fabrication facility, producing quantities from individual prototypes to batch volumes. There is coordination between all processes, resulting in high quality, efficiently made parts. Our streamlined procedure translates means value for our clients.

CHECKS AND REVIEWS

We perform reviews at regular intervals. Unless otherwise requested from our people, the results of the reviews are shared for everyone to see. The goal is to highlight achievements and enable further improvement, which will steer our production associates from bad habits and bad fabrication practices. Our production manager is the gate keeper that makes sure that all sheet metal fabrication jobs are completed successfully.

OUR FABRICATION GOAL

From our designers to production managers to our machine operators, we instill a pride of getting your fabrication job done right the first time and every time. We've been in the sheet metal fabrication business for three generations, and enjoy the process of fabrication. We will exceed our clients' expectations.